Article

Robust sensor fusion

14 February 2024

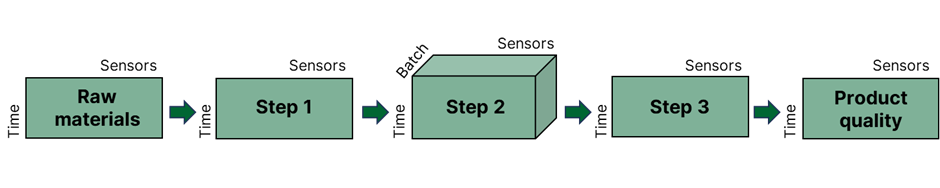

In many industrial applications we have data coming from multiple production steps and data sources, with different time-resolutions, properties, and behaviour. How do you combine these in a holistic way, while making sure that the resulting data is well-suited for automated analysis?

Idletechs is a partner in the EU project Dat4.Zero on Data Reliability and Digitally-enhanced Quality Management for Zero Defect Manufacturing. One of the pilot installations in the project is at Benteler Automotive Raufoss, where the plant produces aluminium profiles for major European car manufacturers. Idletechs’ contribution to the project is to develop an explainable AI (XAI) solution to monitor quality during manufacturing.

Some results from our work in the Dat4Zero project were recently published (Sensor fusion for MSPC) and demonstrates data preprocessing, feature extraction and sensor-fusion for the detection of anomalies. Multivariate Statistical Process Control (MSPC) is then applied for quality monitoring of the extrusion line.

Extrusion is one example of a manufacturing process, where the produced good are processed at multiple stations, thus generating added item properties and process conditions at each location and for each time-point. Successful fault detection and analysis depend on understanding and combining this data in a meaningful way to make sure that causality and correlations are preserved. This can be accomplished by performing holistic sensor fusion that accounts for differences in time, number of parameters, and the natural variation of the process.

Even with the recent advances in AI there is still a need for proper pre-processing of data, often with the help of human interaction, which may include operations such as time alignment by handling different sampling frequencies and lag time, handling of missing values, and detection and handling of outliers. Specific considerations must be made for processes with both continuous and batch process steps due to their different data structures. Of-course we could throw a general machine learning model directly on the raw data, but the number of states will explode, requiring waste amount of training data and extremely complex models to capture all the different combination patterns.

We always advocate for the use of transparent methods that give insight into which process parameters that have changed in the case of out-of-spec situations. This allows understanding limitations in the generated models and combined with important meta-information such as raw material origin this may also lead to generating new knowledge about the process.

1) Data Pre-processing and Sensor-Fusion for Multivariate Statistical Process Control of an Extrusion Process (2023). Frank Westad, Lars Lodgaard, Torbjørn Pedersen. Proceedings of the 3rd International Workshop on Software Engineering and AI for Data Quality in Cyber-Physical Systems/Internet of Things