Anode Quality Monitoring

Anode Quality Monitoring

In general, 2-8% of all produced anodes have some form of defect that can lead to losses in terms of scrapping the anode or that the anode fails and disturbs the aluminium production process. These losses are in the range of 50 to 1000 EUR depending on the severity of the defect and where in the process it is discovered. For a paste plant that produces 500.000 anodes per year, this can amount to 1 to 10 million EUR per year. Idletechs offers a monitoring solution for anode paste plants that provides improved monitoring of critical process parameters and understanding of how different process parameters influence product quality. The solution consists of three modules: Core temperature, Quality Monitoring, and Process Monitoring

The solution provides the following effects:

-

Detect defective anodes and remove them from the process

-

Monitor all anodes that are produced instead of sampling a few times per day. This means going from sampling 1-2% of the production to 100%

-

Improve understanding of process variations, which again enables targeted efforts to reduce these unwanted variations.

-

Find which factors influence anode quality and use this information to optimize production

-

Remove operators from hazardous environments through remote quality monitoring instead of manual inspection

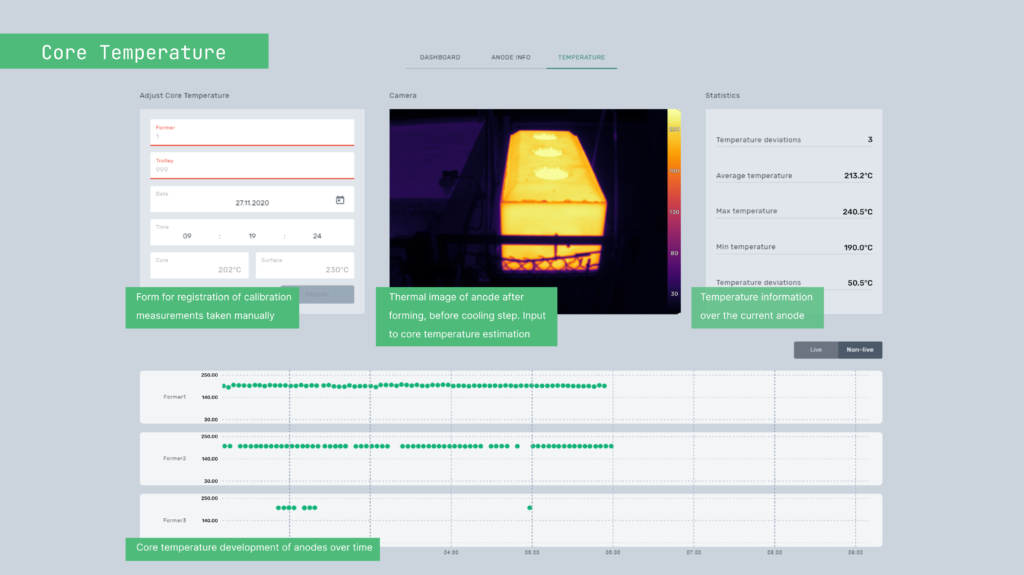

Core temperature

Core temperature of anodes is an important process parameter for product quality and process efficiency. It influences the risk of crack formation and thus it is important to monitor and control in the process. Temperatures are usually measured only for a few anodes per shift. This is done by operators inserting a thermocouple into the anode center. The low sampling rate can lead to many anodes being produced with poor temperature control, or that an incorrect sample is used to change temperature settings. Manual measurements are performed in a hazardous environment with fuming PAH gases and risk of being struck by moving one-tonne anodes. Idletechs adresses this through finding the core temperature by combining thermal cameras and a model that relates surface temperature to core temperature, providing the following benefits:

Temperature estimates within 2℃

Measure temperature of all anodes

Our solution provides temperature measurements of every single anode to within 2℃. This improves process control through continuous measurements and fast feedback to operators. By understanding what the variations in temperature are, and when they happen, fast action can be taken.

See when production stabilizes after downtime or changes to the process

By seeing in when process equipment reach steady state and temperatures stabilization in real-time, it is possible to go from static heuristics on when process is stable to a direct measurement of when this is the case. This means scrapping fewer anodes when starting the plant.

Remove operators from PAH exposed areas

Temperature measurements with thermal cameras are contract-free and remove operators from harm’s way, reducing their exposure to PAH and other hazards, thus improving safety and operators work environment.

Free up capacity to do other more meaningful tasks

Remote measurement of core temperature frees up capacity of operators to do other value adding tasks in the plant.

Quality Monitoring

Currently, quality is based on the density and height of each anode and manual inspection of surface defects such as cracks and broken corners. Inspection is done a few times each shift, and thus only samples a small percentage of all anodes. Manual inspection is difficult and potentially dangerous. The anodes are pitch black, making cracks difficult to see, and operators must be up close for inspection. The anodes are constantly moving and operators risk being squeezed between them. In addition, the anodes are fuming highly cancerous PAH gases. Idletechs quantifies quality based on a combination of process data and thermal images.

Monitor all anodes

By monitoring every single anode the number of defective anodes passing undetected through the quality control can be reduced significantly. Anodes can be automatically rejected based on this information and process settings can be tuned to rectify issues.

Remove operators from hazardous environments

Remote inspection by thermal cameras eliminates PAH exposure and risk of being struck by the one-tonne anodes.

Automatically detect surface defects

Thermal cameras are used to scan all sides of the anodes. The images from the cameras are analyzed using Idletechs’ methods to detect surface defects and are shown to operators in the user interface.

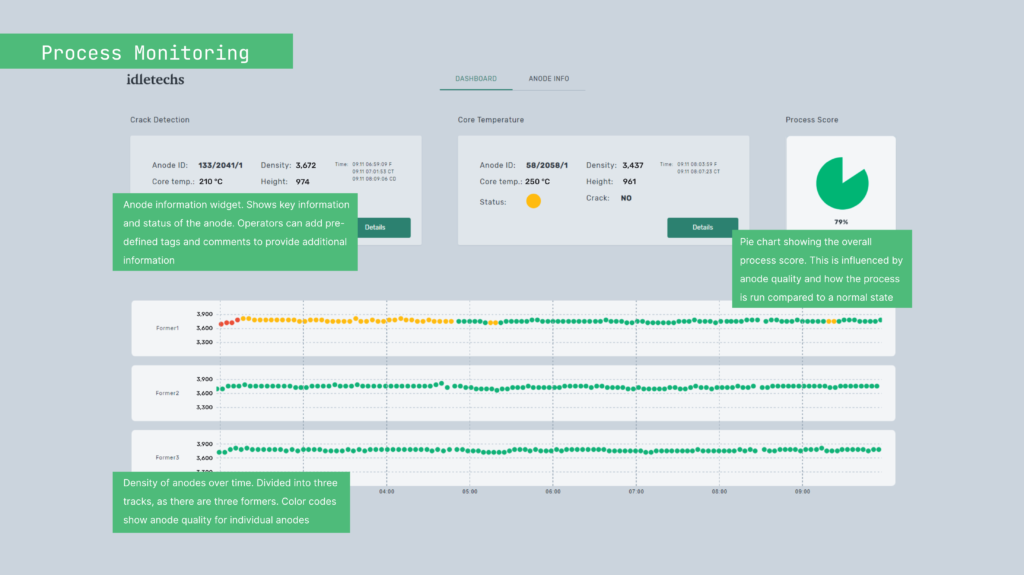

Process Monitoring

A paste plant is monitored by operators with single process parameters plotted on top of each other, along with individual alarm limits for each parameter. Operators can uncover simple process deviations but do not have tools that uncover or understand more complex situations. Viewing individual parameters might not detect out-of-spec behaviour; while multiple parameters can be within individual limits. an issue might arise due to a specific combination of these. Therefore, the system also relies on the correlation patterns of the parameters.

Collect relevant data

Idletechs solution collects relevant data from multiple sources. Thermal images for core temperature and anode quality as well as process data from Historian databases.

Establish normality

Data is processed in Idletechs analytics engine which finds underlying structures in the data and establishes a baseline for normal operating conditions based on both individual and combinations of parameters.

See status at a glance

The dashboard shows status of the paste plant and eventual deviations from normal operating conditions. Operators are provided with high level information on the overall state of the plant and do not have to inspect individual parameters unless there is a required action. Then, users can drill down into more detail to understand root causes.